Products / Uncategorised / Plastic Poly Split Pit P5

Meet the Plastic Poly Pit Split P5. As a Telstra-approved utility access point, it’s a major game-changer. Specifically, it makes network installations and maintenance operations far more efficient. It’s made from UV-stabilized medium-density polyethylene (HDPE). This material guarantees robustness, reliability, and durability. As a result, it’s perfect for numerous infrastructural projects. For instance, telecommunications, electrical, air, rail, and road networks.

Our P5 pit comes with a unique design. It consists of three injection moulded segments, making installations and repairs a breeze. The segments include two opposing sides and a base. This structure allows for quick assembly and disassembly, making infrastructure maintenance a snap.

The P5 pit is perfect for supporting live conduits, leading to interruption-free repair operations. Moreover, you can adjust it to existing infrastructure and for modified depth installations. This makes the Plastic Poly Split Pit P5 a versatile solution. It also boasts impressive resistance to moisture, chemicals, and impact. Hence, it’s a safe and reliable choice for underground utility access. From landscape areas and sports fields to lighting pits and domestic environments, it fits everywhere.

Our P5 pit comes with a Class A load rating. However, you can upgrade it to Class B under certain conditions. This flexibility allows for various project requirements, ensuring optimal performance and safety.

Convic Australia offers multiple cover options for the Plastic Poly Split Pit P5. These include concrete, composite, cast iron, and GMS covers. With varying load ratings, from Class A to Class C, they provide secure and reliable access points for diverse applications.

Our P5 pit design demonstrates our commitment to eco-friendly practices. It’s lightweight, leading to efficient transportation, storage, and handling. Consequently, it reduces the carbon footprint. It also minimizes the risk of breakage and health hazards.

Convic Australia, a reputed supplier, is proud to offer the Plastic Poly Pit P5. This product is recognized and approved by major Australian authorities in telecommunications and energy supply. It’s an ideal choice for secure, efficient, and sustainable underground utility access. Need more information? Contact us today, and we’ll help you optimize your project operations.

Weight (kg) |

Length (mm) |

Width (mm) |

Depth (mm) |

Clear Opening |

| 9 | 713 | 453 | 630 | 653 x 400 |

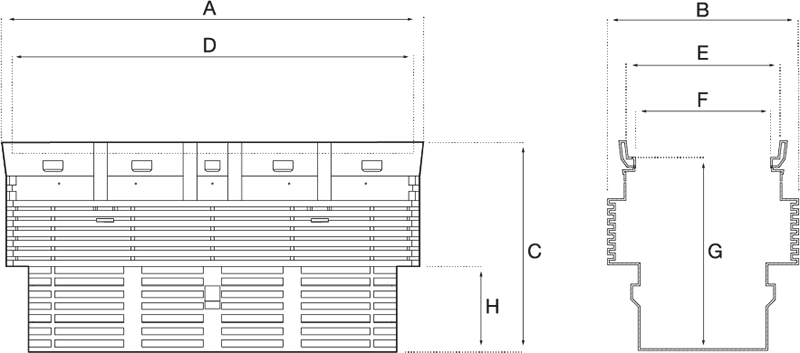

A |

B |

C |

D |

E |

F |

G |

H |

| 713 | 453 | 630 | 653 | 400 | 332 | 585 | 230 |

*All measurements in millimetres

| HDPE | |

| Compressive strength: | 58MPa D-695 |

| Flexural strength: | 15MPa D-790 |

| Tensile strength: | 14Mpa D638 |

| Water absorption: | +0.31% D-570 |

| Water vapour transmission: | WVT 0.1392g/m2 – 1,592hrs E96 |

| Coefficient of friction (Mannings): | n=0.010 |

| Chemical resistance | Good |

AS/NZ 3996